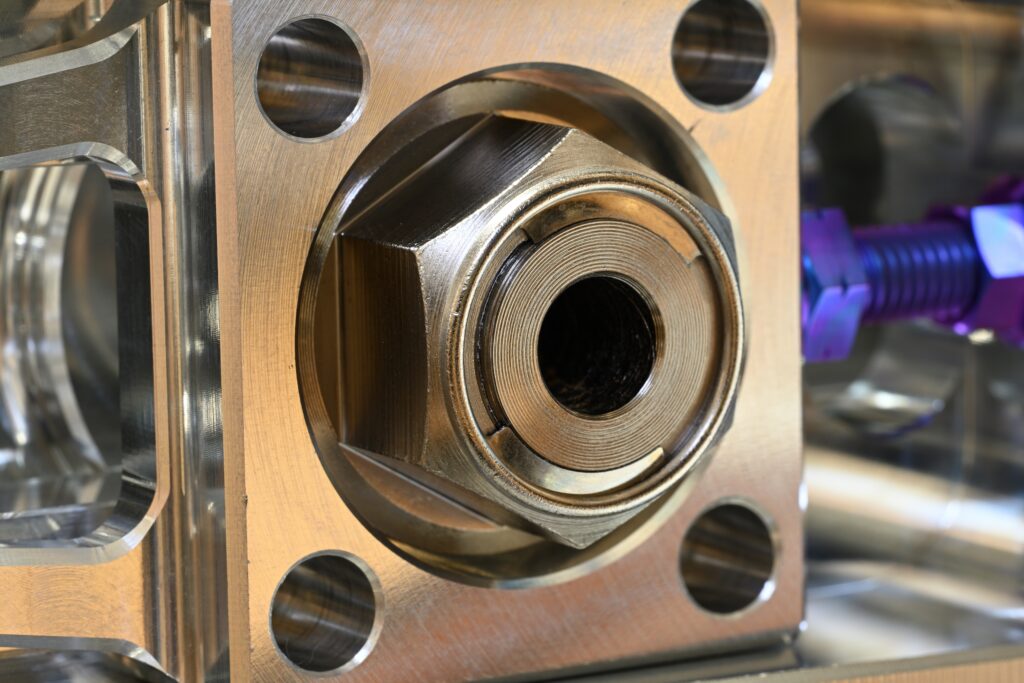

Paladin High-Phos electroless Nickel

A Breaththrough In CHemistry

Firstly, it came about from certain requirements from the oil and gas industry. They wanted longer service life for their tooling. That is where we started with this. We found different applications that could benefit from this corrosion resistance, particularly in the aerospace connector industry. Often, you need to use duplex coatings, such as electroless nickel with cadmium, electroless nickel with zinc nickel, and hexavalent chromate. This can potentially eliminate some of those extra coatings and the hexavalent chromium.

We found applications in the semiconductor industry, where some semiconductor tools are exposed to a highly corrosive gaseous environment. This should be able to protect those harsh environments as well.